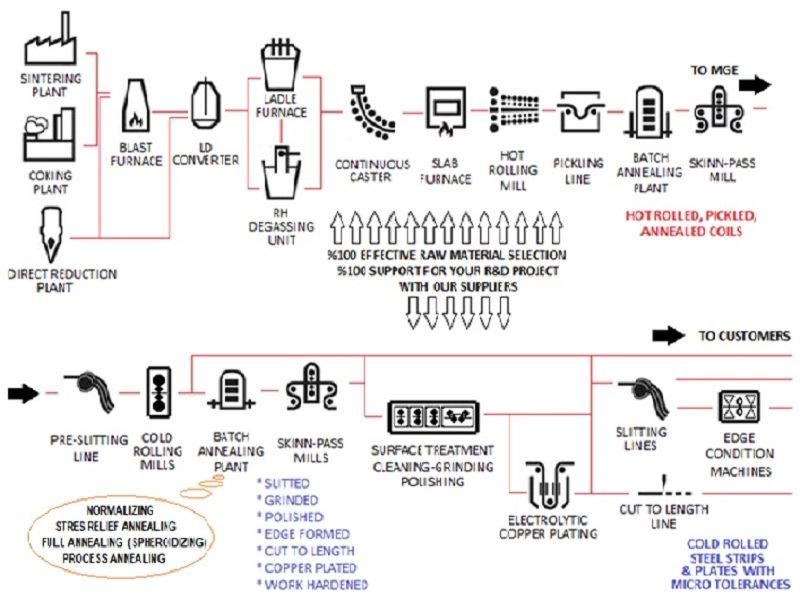

RAW MATERIALS

Hot, acidic and annealed imported steel coils in our factory to import our steel sheet begins to begin our processes. Introduction After the chemical and physical tests performed by our Quality Control Department, our raw materials which are 100% approved are transferred to production.

PRE SLITTING

Our raw materials passing through quality approval are combined in accordance with customer orders and widened to our widths. Most of the controls are automated as the first phase of our production is sensitive to all processes.

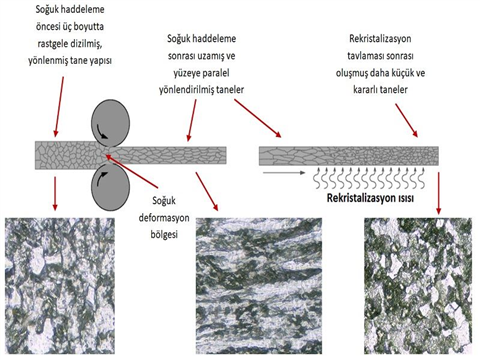

COLD ROLLING

We provide the following features to our materials as a result of the continuous deforming of our raw materials, which are coming from the pre-slitting, with a special profile and detek roll in our reversed cold rolls.

High dimensional and dimensional accuracy

Increased surface quality

High mechanical strength, tough material production against fatigue

Parallel and oriented grains

Small grain structure after recrystallization

ANNEALING

In addition to all the annealing processes in our factory, we can carry out special annealing processes and combined annealing processes for our raw materials. We offer perfect service to our customers who are doing precision cutting with our combined processes.

Stress relief annealing

Normalization annealing

Isothermal annealing

Softening (Globalization) annealing

Recrystallization annealing

Grain improvement annealing

Polygonal annealing

Recrystallization and grain magnification annealing

Combination annealing: Stress relief annealing + Keyed phase change-specificization + isothermal annealing + re-granulation + long-term globalization + homogenization + controlled cooling.

PRECISION SLITING

Our precision slitting machines with 406.4 mm (16 ") and 508mm (20") core diameters are capable of winding up to 1397mm (55 ") outer diameter and serve up to our maximum production width of 7mm width (workable up to non-standard 5mm) We are able to supply burr-free, planar raw materials to our customers with our precision slitting machines with an average thickness of 1mm and 34 mm 7mm slitting width and 200 meters / minute speed.

CUT TO LENGTH

Specially designed and produced by our size cuts, including heat-treated materials can make the surface operations, very precisely in the perfect planarity of the materials can be straightened and plate, no hand can be packaged. From 0,3mm to 6,20mm, we can serve our customers' plate needs with our 500mm width.

SURFACE TREATMENT

Satine surfaces with 5-station special surface treatment line, extra shiny surface appearance while we can make oil-free operations.

EDGE FORMING

Production can be done with cold forming and machining in desired edge forms and customers can be served in jumbo bobbins.

MGE

Metal Development Industry

Phone

444 8 643

info@mge.com.tr